Key Takeaways

| Dredger Pump Basics | Performance Factors | Maintenance Tips |

|---|---|---|

|

|

|

Ever wonder what keeps dredging projects running smoothly? The answer is simpler than you might think: a properly functioning dredger pump.

I’ve spent years researching dredging equipment, and I can tell you this with confidence — your dredger pump can make or break your entire operation.

In this comprehensive guide, we’ll dive deep into everything you need to know about dredger pumps, from basic components to advanced troubleshooting. By the end, you’ll understand exactly how to select, operate, and maintain these critical pieces of equipment.

What is a Dredger Pump? Understanding the Heart of Dredging Operations

A dredger pump is the powerhouse behind any successful dredging operation. Think of it as the heart that keeps the entire system alive.

In simple terms, a dredger pump creates the suction force needed to pull sediment from underwater locations and push it through pipelines to disposal or reclamation sites.

Why are dredger pumps so important? Because without them, moving massive volumes of underwater material would be practically impossible.

The dredger pump plays a pivotal role in material transport, moving slurry (that’s a mixture of water and excavated material) from the seabed through pipelines to wherever it needs to go. How efficiently this happens directly impacts your entire operation’s productivity.

Figure 1: Material flow through a typical dredger pump system

Dredger pumps come in various types, including:

- Centrifugal pumps – The most common type, using rotating impellers to create flow

- Positive displacement pumps – Used for highly viscous or dense materials

- Jet pumps – Utilizing high-pressure water jets to create suction

Each type serves specific applications based on material density, distance requirements, and project conditions. But for most major dredging operations, centrifugal pumps rule the roost.

According to a study published in Research Gate, properly configured dredger pumps can improve operational efficiency by up to 30% compared to poorly matched systems.

Dredger Pump Configurations: Inboard vs. Outboard Systems

One of the biggest decisions you’ll face when choosing a dredger pump is the configuration: inboard or outboard. This choice affects everything from dredging depth to maintenance access.

Here’s how they stack up:

| Feature | Inboard Pumps | Outboard Pumps |

|---|---|---|

| Location | Inside dredger hull | Mounted externally, near cutter head |

| Suction Efficiency | Moderate | Higher, especially in deeper waters |

| Maintenance Access | Easier, inside vessel | More challenging, underwater access |

| Suitable Applications | Shallow waters, simpler projects | Deep waters, dense materials |

Inboard pumps shine in shallow water operations where maintenance accessibility is crucial. They’re sheltered inside the hull, making them easier to service and less exposed to the elements.

On the flip side, outboard pumps excel in deeper operations. By positioning the pump closer to the material source, they reduce the distance material must travel before reaching the pump, dramatically improving suction efficiency.

When deciding between configurations, consider your typical:

- Working depths

- Material densities

- Maintenance capabilities

- Transportation requirements

For projects requiring regular relocation between sites, the transportability of your dredging equipment should weigh heavily in your decision.

Key Components and Design Considerations of Dredger Pumps

Understanding the anatomy of a dredger pump helps you make smarter maintenance and purchasing decisions. These powerhouses consist of several critical components working in harmony.

The main components include:

- Impeller – The rotating part that creates flow and pressure

- Casing – Dual-structure housing that contains the slurry

- Shaft – Transfers power from the motor to the impeller

- Bearings – Support the shaft and reduce friction

- Seals – Prevent leakage and bearing contamination

- Suction and discharge connections – Entry and exit points for slurry

Material selection is absolutely critical for dredger pumps. Unlike clean water pumps, these workhorses must withstand incredibly abrasive conditions.

“The choice of materials in dredger pump construction can mean the difference between a pump lasting six months versus three years in severe conditions.” – Dredging Engineering Manual

Most modern dredger pumps use high-chromium cast iron for impellers and casings. This material withstands the abrasive nature of sand, gravel, and other sediments, extending the pump’s service life and reducing how often you’ll need to perform maintenance.

Beyond materials, the impeller design deserves special attention. Unlike clean water pumps, dredger pump impellers feature fewer, non-overlapping blades. This design choice isn’t random – it creates smoother flow paths for abrasive mixtures, reducing direct contact with solids and extending pump life.

Another critical design feature is the modular construction of modern dredger pumps. This approach allows for disassembly and transportation via standard containers, making deployment possible even in remote locations.

For a deeper dive into how these components integrate with cutter suction dredgers, check out this comprehensive guide.

Working Principles of Dredger Pumps in Action

To truly master dredger pump selection and operation, you need to understand how these machines actually work in real-world conditions.

Here’s the sequence in plain English:

- The cutter head loosens soil and rock, creating a slurry mixture

- The dredger pump creates negative pressure (suction) at the intake

- This suction pulls the slurry mixture into the pump

- The rotating impeller accelerates the slurry

- Centrifugal force pushes material toward the discharge connection

- The slurry exits through pipelines to its destination

What makes dredger pumps fascinating is how dramatically their performance changes based on what they’re pumping. Unlike clean-water pumps that maintain consistent performance curves, dredger pumps behave differently when handling slurry.

As slurry concentration increases, you’ll notice:

- Increased head pressure requirements

- Higher shaft power demands

- Decreased overall efficiency

This variability means your pump must be designed with real-world sediment conditions in mind, not just clean water performance figures.

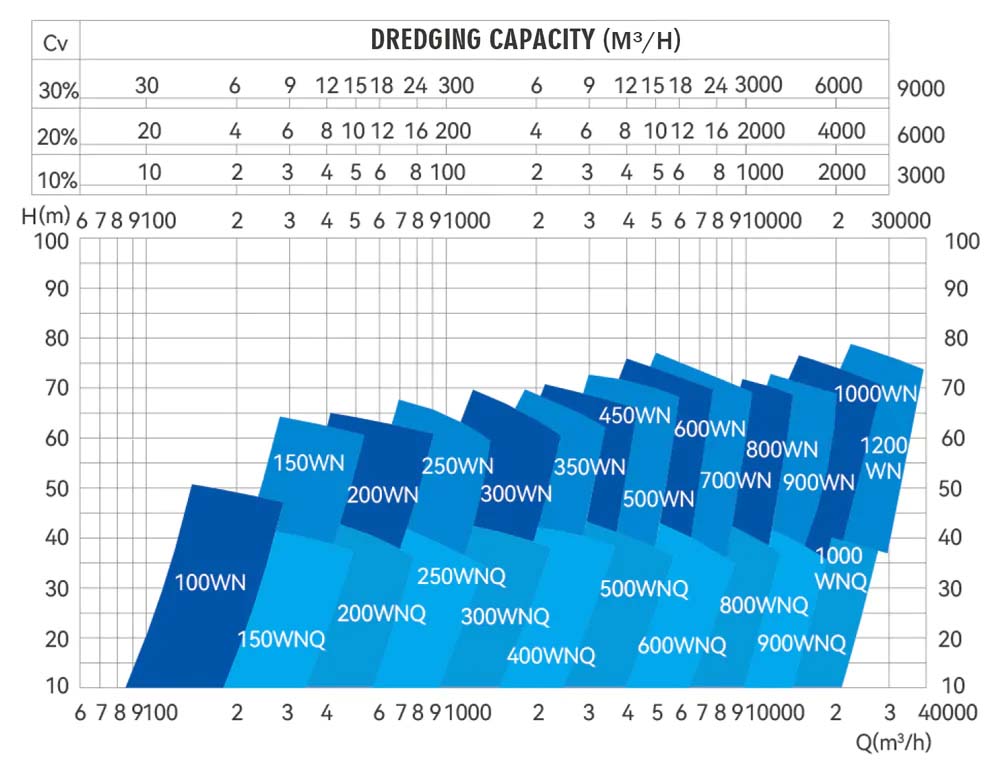

Typical performance parameters for mid-sized dredger pumps include:

- Flow rates: 2,500-4,500 m³/h

- Head pressure: 20-70 meters

- Power consumption: 700-2,000 kW

- Maximum solid size: 100-200 mm

The specific cutter teeth configuration directly impacts how material enters your dredger pump, affecting overall system efficiency.

Advanced Technology in Modern Dredger Pumps

Dredger pump technology has evolved dramatically in recent years. These advances have transformed what’s possible in dredging operations.

Let’s explore the game-changing innovations:

Automation and Remote Monitoring

Gone are the days of manual pump adjustments. Modern dredger pumps feature sophisticated control systems that allow operators to make real-time adjustments from a control room.

These systems typically include:

- Flow meters for accurate production monitoring

- Density sensors to optimize slurry concentration

- Pressure monitors to prevent cavitation

- Automated control algorithms for consistent performance

With remote monitoring capabilities, operators can adjust pump performance in real-time, dramatically improving both safety and efficiency.

Energy Efficiency Improvements

With growing environmental concerns and rising fuel costs, modern dredger pumps emphasize energy efficiency. Newer designs reduce fuel consumption and emissions without sacrificing performance through:

- Optimized impeller designs that reduce turbulence

- Variable frequency drives for precise power control

- Advanced materials that reduce friction

- Improved hydraulic profiles for smoother flow

According to the Central Dredging Association, these improvements can reduce energy consumption by 15-25% compared to older designs.

CFD Simulation for Design Optimization

Perhaps the most exciting advancement is the use of Computational Fluid Dynamics (CFD) in dredger pump design. This technology allows engineers to:

- Visualize internal flow patterns

- Predict performance under various conditions

- Optimize designs before physical prototyping

- Reduce development time and costs

By analyzing these simulations, engineers can identify potential wear points, flow restrictions, and efficiency losses before they become real-world problems.

Figure 2: CFD simulation showing velocity distribution

Figure 3: Advanced control system interface

Performance Optimization: Getting the Most from Your Dredger Pump

Performance optimization isn’t just about buying the biggest pump – it’s about smart configuration and operation. Here’s how to maximize your dredger pump’s efficiency:

Series Pump Configurations for Increased Pressure

For challenging projects requiring long-distance transport or significant vertical lift, a single pump often isn’t enough. This is where series pump configurations shine.

By connecting multiple pumps in sequence, you can:

- Dramatically increase total head pressure

- Maintain flow rates over longer distances

- Handle more challenging material properties

However, series configurations significantly increase the pressure demands on your gland (seal) water system. This requires careful design considerations to prevent failures.

Variable-Frequency Operation Advantages

Fixed-speed operation is the enemy of efficient dredging. Due to constantly changing slurry properties, your pump needs to adapt in real-time.

Variable-frequency drives allow your pump to:

- Adjust to changing material conditions

- Prevent pipeline blockages

- Maintain optimal pressure

- Reduce energy consumption during lighter loads

For gland water systems specifically, variable-frequency centrifugal pumps are recommended, enabling real-time pressure and flow adjustments based on pump speed.

Power Matching Between Engine and Pump

One of the most common mistakes in dredger pump operation is improper power matching between the pump and its drive engine.

The power matching coefficient between dredge pump and diesel engine typically ranges from 0.7 to 0.9. Anything outside this range leads to problems:

- Too little power: Engine overloading, black smoke, reduced performance

- Too much power: Fuel inefficiency, increased wear, poor economics

Proper matching ensures your engine operates in its optimal range regardless of slurry conditions, maximizing both performance and fuel efficiency.

For operations requiring versatile equipment that can handle multiple material types, sand pump machines offer complementary capabilities worth exploring.

Maintenance and Troubleshooting Guide for Dredger Pumps

Even the best-designed dredger pump requires proper maintenance. Following a structured approach saves money and prevents catastrophic failures.

Common Issues and Solutions

| Problem | Possible Causes | Solutions |

|---|---|---|

| Reduced flow rate |

|

|

| Excessive vibration |

|

|

| Seal failure |

|

|

Preventative Maintenance Schedule

Follow this schedule to maximize uptime and minimize emergency repairs:

- Daily:

- Visual inspection for leaks

- Check gland water flow and pressure

- Monitor operating temperatures

- Listen for unusual noises

- Weekly:

- Inspect drive belts/couplings

- Check bearing lubrication

- Clean suction strainers

- Monthly:

- Check impeller clearance

- Inspect shaft alignment

- Analyze vibration readings

- Annually:

- Complete disassembly and inspection

- Replace wear components

- Recalibrate instruments

Extending Pump Lifespan Through Proper Care

Smart maintenance practices significantly extend dredger pump life:

- Use independent seal water circuits for suction and shaft ends, as they have different sealing requirements

- Implement standby pumps for critical components to enhance system redundancy

- Operate within design parameters – pushing beyond specifications rapidly accelerates wear

- Monitor slurry density – higher densities dramatically increase wear rates

- Train operators in proper startup and shutdown procedures

According to industry best practices, proper maintenance can extend dredger pump life by 40-60% compared to reactive maintenance approaches.

Selecting the Right Dredger Pump for Your Project

Choosing the right dredger pump involves balancing several factors. Let’s break down the selection process:

Assessment Criteria for Project Requirements

Start by analyzing these key project parameters:

- Material characteristics:

- Density and specific gravity

- Particle size distribution

- Abrasiveness and hardness

- Project logistics:

- Dredging depth requirements

- Transport distance needed

- Production rate targets

- Operational constraints:

- Available power sources

- Environmental restrictions

- Maintenance facilities

These factors form the foundation of your pump selection process.

Customization Options Available

Modern dredger pumps offer extensive customization options:

- Impeller design – Closed, semi-open, or open configurations based on material properties

- Material construction – From standard high-chrome to exotic alloys for extreme conditions

- Drive systems – Direct, belt, or hydraulic drives for different applications

- Control systems – Basic manual controls to fully automated operation

Working with manufacturers who understand cutter suction dredger systems helps ensure your pump integrates seamlessly with other components.

Cost vs. Performance Considerations

While initial cost matters, total lifecycle expenses should drive your decision:

| Cost Factor | Impact on Initial Cost | Impact on Lifecycle Cost |

|---|---|---|

| Premium materials | Increases by 20-40% | Decreases by 30-50% (longer life) |

| Advanced controls | Increases by 15-30% | Decreases by 10-25% (efficiency gains) |

| Modular design | Increases by 5-15% | Decreases by 20-35% (easier maintenance) |

| Oversized capacity | Increases by 25-40% | Variable (depends on utilization) |

According to research published in Engineering, optimizing pump selection can reduce operational costs by up to 35% over the equipment lifespan.

FAQs About Dredger Pumps

Let’s address the most common questions about dredger pumps:

What is the maximum dredging depth achievable with dredger pumps?

Modern dredger pumps can reach depths of 25-35 meters when using outboard configurations. Specialized deep-water systems can reach up to 100 meters, but these require complex submersible pump arrangements with specialized power delivery systems.

How does slurry concentration affect dredger pump performance?

As slurry concentration increases, head pressure requirements rise, efficiency decreases, and power demand increases. A pump operating at 30% solids concentration typically requires 40-60% more power than the same pump handling clear water.

What factors determine the need for an underwater pump?

Consider underwater (outboard) pumps when:

- Working depths exceed 15-20 meters

- Dealing with high-density materials

- Operating in areas with significant water level fluctuations

- Maximum production rates are critical

How is the dredge pump protected from abrasive wear?

Protection methods include:

- High-chromium alloy construction (25-30% chromium content)

- Ceramic liners for extreme conditions

- Optimized impeller designs with fewer blades to reduce contact points

- Replaceable wear plates at high-impact areas

- Controlled flow paths to minimize turbulence

What are typical power requirements for dredger pumps?

Power requirements vary widely based on size and application:

- Small dredgers: 250-500 kW

- Medium dredgers: 500-1,200 kW

- Large dredgers: 1,200-3,000+ kW

The power matching coefficient between pump and engine typically ranges from 0.7-0.9 to allow for operational flexibility.

Conclusion: Making an Informed Decision on Dredger Pumps

By now, you should have a solid understanding of what makes dredger pumps tick and how to select the right one for your project.

Remember these key takeaways:

- Dredger pumps are the heart of any successful dredging operation

- Configuration choice (inboard vs. outboard) should match your specific project needs

- Material selection dramatically impacts pump lifespan and maintenance requirements

- Advanced technologies like automation and CFD optimization improve efficiency

- Proper maintenance extends service life and reduces costly downtime

The right dredger pump isn’t just about power or size – it’s about finding the perfect balance between capacity, durability, efficiency, and cost for your unique requirements.

When evaluating options, prioritize manufacturers with proven track records, comprehensive support networks, and deep industry expertise. The small premium paid initially for quality equipment pays dividends throughout your project’s lifecycle.

Ready to take the next step?

Whether you’re starting a new project or upgrading existing equipment, proper dredger pump selection is crucial for operational success. Consult with industry specialists to ensure your equipment matches your exact needs and operating conditions.

Remember: A well-chosen dredger pump doesn’t just move material – it transforms the economics of your entire operation.