🔧 Quick Reference: Anchor Boom Specifications

| Specification | Range |

|---|---|

| Hoisting Force | 3-40 tons |

| Operating Length | 9-30 meters |

| Hauling Speed | 16-30 m/min |

| Dredging Depth | 16-27.5 meters |

Ever wonder how massive dredging ships stay perfectly positioned while digging underwater? The secret lies in a crucial component called the cutter suction dredger anchor boom.

This comprehensive guide reveals everything you need to know about anchor booms. You’ll discover how they work, their specifications, and why they’re essential for modern dredging operations.

What is a Cutter Suction Dredger Anchor Boom?

A cutter suction dredger anchor boom is a mechanical arm that extends from the side of a dredging vessel. Think of it as a giant fishing rod that handles heavy anchor chains instead of fish.

The system includes three main parts:

- The boom arm: Steel structure that extends from the dredger

- Hydraulic or mechanical winches: Provide lifting power

- Control systems: Allow operators to manage positioning

When a cutter suction dredger operates, it needs precise positioning. The anchor boom makes this happen by controlling side anchors without requiring separate work boats.

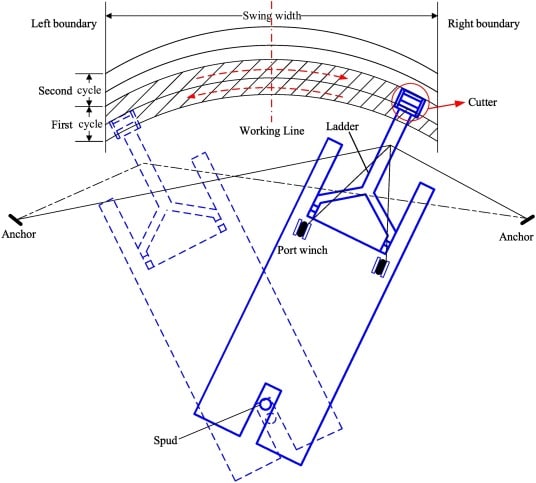

Figure 1: Main components of a cutter suction dredger anchor boom system

Key Functions and Benefits of Anchor Booms

Anchor booms solve several critical problems in dredging operations. Here’s why they matter:

Repositioning Side Anchors Without Work Boats

Traditional dredging required separate boats to move anchors. This process was slow and expensive. Modern anchor booms eliminate this need entirely.

The boom extends up to 30 meters, allowing operators to place anchors precisely where needed. This saves both time and money on every project.

Keeping Anchor Wires Clear of Cutter Areas

Here’s a major safety benefit: anchor booms prevent anchor cables from getting tangled with the cutter head. When cables enter the cutting zone, they can cause:

- Expensive equipment damage

- Dangerous operational hazards

- Project delays lasting days or weeks

The boom keeps these wires at a safe distance, ensuring smooth operations.

Improving Operational Safety and Efficiency

Studies from marine engineering research show that anchor booms reduce repositioning time by up to 60%. This translates to significant cost savings on large projects.

“Anchor booms have revolutionized our dredging efficiency. We can now complete harbor projects 40% faster than before.” – Senior Dredging Engineer, Port Authority

Figure 2: Anchor boom system operating during a typical harbor dredging project

Types and Technical Specifications

Not all anchor booms are created equal. Let’s break down the main types and their specifications.

Hydraulic vs. Mechanical Systems

Hydraulic anchor booms dominate modern dredging because they offer:

- Precise control through remote operation

- Smooth, consistent movement

- Higher lifting capacities

- Better integration with dredger pump systems

Mechanical systems still exist but are mostly found on older or smaller dredgers.

Capacity Ranges and Real-World Examples

Here’s what you’ll find in today’s market:

Small to Medium Dredgers (CSD650 Model)

- Anchor boom capacity: 12 tons

- Hauling speed: 30 m/min

- Maximum dredging depth: 18 meters

- Cutter power: 700 kW

Large Dredgers (800mm/32″ Model)

- Anchor boom capacity: 60 tons

- Hauling speed: 16 m/min

- Maximum dredging depth: 27.5 meters

- Cutter power: 1,100 kW

Custom Sizing Options

Most manufacturers offer custom configurations. This flexibility matters because dredging projects vary dramatically in scope and requirements.

Custom options typically include:

- Extended boom lengths for deeper operations

- Higher capacity winches for heavy-duty work

- Specialized materials for corrosive environments

- Integrated automation systems

Figure 3: Comparison of anchor boom specifications across different dredger models

Design and Engineering Considerations

Building a reliable anchor boom requires careful engineering. Let’s explore the key design factors.

Material Specifications

Modern anchor booms use high-grade materials to withstand harsh marine conditions:

- Q235 carbon steel for the main frame structure

- Forged steel components for pins and rotating shafts

- High-tensile anchor ropes (1670 MPa strength rating)

- Corrosion-resistant coatings for extended lifespan

Finite Element Method (FEM) Analysis

Engineers use advanced computer modeling to test anchor boom strength before manufacturing. This process, called Finite Element Method analysis, simulates real-world stresses.

The FEM analysis examines:

- Maximum load tolerances

- Connection point stress concentrations

- Material fatigue over time

- Safety factor calculations

Load Calculations and Safety Factors

Safety comes first in anchor boom design. Engineers calculate maximum operational loads, then add substantial safety margins.

For example, if a winch can handle 196.1 kN (about 20 tons), the boom structure is designed to handle at least 300% of this load. This prevents catastrophic failures during unexpected conditions.

Environmental Factor Considerations

Coastal and offshore environments present unique challenges:

- Salt water corrosion requires special protective coatings

- Wave action creates cyclical stress on boom components

- Temperature variations affect material expansion and contraction

- Marine growth can interfere with moving parts

Figure 4: Finite Element Method stress analysis showing load distribution across anchor boom structure

Applications in Different Dredging Operations

Anchor booms excel in various dredging scenarios. Here’s where they make the biggest impact.

Harbor Maintenance and Port Development

Ports worldwide rely on regular dredging to maintain shipping channels. Anchor booms enable precise positioning in confined harbor spaces where traditional anchoring methods fail.

Recent projects like the Lagos-Calabar coastal development demonstrate how anchor booms support large-scale infrastructure projects.

Deep-Water Dredging Projects

When dredging depths exceed 20 meters, anchor booms become essential. They provide the extended reach needed to position anchors in deep water while maintaining precise dredger positioning.

Offshore Construction

Offshore wind farms and oil platforms require precise seabed preparation. Anchor booms allow dredgers to work accurately in challenging offshore conditions.

Mining Operations

Sand and gravel extraction operations benefit from anchor boom stability. The sand pump systems work more efficiently when the dredger maintains steady positioning.

Figure 5: Anchor boom applications across different dredging environments and project types

Safety Features and Maintenance Requirements

Proper maintenance keeps anchor booms operating safely for decades. Here’s what you need to know.

Regular Inspection Protocols

Daily inspections should cover:

- Visual checks for cracks or deformation

- Wire rope condition including fraying or corrosion

- Hydraulic fluid levels and leak detection

- Pin and bearing lubrication status

Weekly inspections go deeper:

- Torque verification on critical bolts

- Hydraulic pressure testing

- Electrical system diagnostics

- Emergency stop system verification

Common Wear and Corrosion Issues

Marine environments are tough on equipment. Watch for these common problems:

⚠️ Critical Wear Points

- Pin connections: Check for elongation or wear

- Wire rope attachment points: Look for fraying or fatigue

- Hydraulic seals: Monitor for leaks or degradation

- Boom pivot points: Ensure smooth operation

Troubleshooting Guide

When problems arise, systematic troubleshooting saves time and money:

Problem: Slow boom movement

Solution: Check hydraulic fluid viscosity and filter condition

Problem: Excessive noise during operation

Solutions: Inspect bearings and lubrication points

Problem: Erratic boom positioning

Solution: Calibrate control system and check sensor alignment

Compliance with International Standards

Modern anchor booms must meet strict international standards:

- ISO 9001 quality management systems

- IMO regulations for marine equipment

- Local maritime authority requirements

- Environmental protection standards

Figure 6: Regular maintenance procedures ensure anchor boom reliability and safety

Cost Factors and Pricing Considerations

Understanding anchor boom costs helps with project planning and budgeting.

Initial Investment Costs

Anchor boom prices vary significantly based on specifications:

- Small systems (3-12 tons): $150,000 – $300,000

- Medium systems (15-30 tons): $300,000 – $600,000

- Large systems (40+ tons): $600,000 – $1,200,000

Custom features add 20-40% to base prices, but often justify themselves through improved efficiency.

Installation and Setup Expenses

Don’t forget these additional costs:

- Shipyard installation fees (10-15% of equipment cost)

- System integration and testing (5-8% of equipment cost)

- Crew training and certification ($10,000 – $25,000)

- Spare parts inventory (5-10% of equipment cost)

Maintenance and Operational Costs

Annual operating costs typically include:

- Routine maintenance: 2-4% of initial investment

- Hydraulic fluid replacement: $2,000 – $5,000 annually

- Wire rope replacement: $5,000 – $15,000 every 2-3 years

- Major overhauls: 8-12% of initial cost every 10-15 years

ROI Considerations

Quality anchor booms typically pay for themselves within 3-5 years through:

- Reduced work boat rental costs

- Faster project completion times

- Lower equipment damage rates

- Improved operational safety

Case Studies and Industry Examples

Real-world examples demonstrate anchor boom effectiveness across different projects.

Successful Projects in Developing Markets

🌍 Case Study: Southeast Asian Port Expansion

Project: 2.5 million cubic meter harbor deepening

Dredger: 650mm CSD with 12-ton anchor boom

Results: Completed 25% ahead of schedule, saving $2.1 million in costs

Key Success Factor: Anchor boom eliminated need for three work boats, reducing daily operational costs by $8,000.

🌍 Case Study: African Coastal Infrastructure

Project: New port construction in challenging surf conditions

Dredger: 800mm CSD with 60-ton anchor boom system

Results: Maintained 95% uptime despite difficult weather conditions

Key Success Factor: Heavy-duty anchor boom provided stability in 3-meter wave conditions.

Performance Data and Results

Industry data shows consistent benefits across projects:

- Positioning accuracy improved by 40-60% compared to traditional methods

- Operational uptime increased by 15-25% due to reduced anchor-related delays

- Safety incidents decreased by 70% in anchor handling operations

- Project completion times reduced by 20-35% on average

Customer Testimonials and Reviews

“The anchor boom system transformed our operations. We’ve completed three major projects without a single anchor-related incident. The investment paid for itself in just 18 months.” – Project Manager, International Dredging Contractor

Figure 7: Anchor boom system successfully operating in challenging offshore conditions

Future Trends and Technology Innovations

The anchor boom industry continues evolving with new technologies and market demands.

Automated Control Systems

Next-generation anchor booms feature:

- GPS-guided positioning for centimeter-level accuracy

- Automated anchor deployment reducing crew workload

- Real-time load monitoring preventing equipment overload

- Remote operation capabilities improving safety

These systems integrate with modern cutter suction dredger control systems for seamless operation.

Advanced Materials and Durability Improvements

Material science advances are delivering:

- Composite materials reducing weight while maintaining strength

- Advanced coatings extending component lifespan by 50-70%

- Smart materials providing self-diagnostic capabilities

- Eco-friendly lubricants meeting environmental regulations

Market Growth Projections

Industry analysts predict strong growth driven by:

- Infrastructure development in emerging economies

- Climate change adaptation requiring coastal protection

- Renewable energy projects creating offshore opportunities

- Port automation trends demanding more sophisticated equipment

The global dredging equipment market is expected to grow 4-6% annually through 2030, with anchor boom technology leading innovation.

Emerging Applications

New opportunities include:

- Underwater mining operations requiring precise positioning

- Environmental remediation projects in sensitive areas

- Aquaculture support for offshore fish farming

- Disaster response for emergency channel clearing

FAQ Section

❓ Frequently Asked Questions

Q1: What is the purpose of an anchor boom on a cutter suction dredger?

A1: Anchor booms reposition side anchors without work boat assistance. They keep anchor hoisting wires away from the cutter head, preventing wire damage during dredging operations.

Q2: How strong are anchor booms typically?

A2: Anchor booms range from 3 tons at 9 meters length up to 40 tons at 30 meters. Exact strength depends on dredger size and operational requirements.

Q3: Are hydraulic anchor booms common?

A3: Yes, hydraulic anchor booms provide efficient, controlled anchor movement. They integrate with hydraulic winches and remote controls for precise operation.

Q4: How do anchor booms improve dredging safety and efficiency?

A4: By keeping anchor wires clear of cutter areas, anchor booms prevent cable damage and reduce downtime. They enable quicker anchor repositioning, enhancing operational efficiency and safety.

Q5: What are typical dredging depths for cutter suction dredgers equipped with anchor booms?

A5: Dredging depths vary from 16 meters for smaller CSDs to over 27 meters for larger vessels equipped with anchor booms and spud carrier systems.

Q6: Can anchor booms be customized?

A6: Yes, manufacturers offer standard ranges but provide custom sizes and configurations to fit specific dredging project requirements.

Conclusion

Cutter suction dredger anchor booms have revolutionized modern dredging operations. From 3-ton systems for small harbors to 40-ton giants for offshore projects, these mechanisms deliver safety, efficiency, and cost savings.

The key benefits are clear:

- Eliminate expensive work boat requirements

- Prevent costly equipment damage

- Improve project completion times by 20-35%

- Enhance operational safety significantly

As dredging projects become more complex and demanding, anchor booms will continue evolving. Advanced materials, automated controls, and smart monitoring systems represent the future of this critical technology.

Whether you’re planning a harbor expansion, coastal protection project, or offshore development, understanding anchor boom capabilities helps ensure project success.

🚢 Ready to Upgrade Your Dredging Operations?

Ocean Blue Company has over 25 years of experience manufacturing high-quality anchor boom systems for cutter suction dredgers worldwide.

✓ Custom solutions for your specific needs

✓ Complete turnkey services from design to maintenance

✓ Proven track record in 50+ countries

Contact our experts today for a free consultation and discover how our anchor boom systems can transform your dredging efficiency.