Quick Reference: Cutter Suction Dredger Spud Specifications

| Specification | Range | Key Benefit |

|---|---|---|

| Load Capacity | 3 to 125 tons | Heavy-duty anchoring stability |

| Operating Depth | Up to 30 meters | Deep water positioning control |

| Material Grade | Grade A Steel | Corrosion resistance durability |

| System Type | Hydraulic/Fixed | Flexible operation modes |

What is a Cutter Suction Dredger Spud?

A cutter suction dredger spud works like a massive anchor that keeps dredging vessels perfectly positioned during operations. Think of it as a giant steel pole that penetrates the seabed to create a stable pivot point.

Spud system providing stable anchoring for precise dredging operations

The spud serves three critical functions in dredging operations:

- Anchoring stability: Prevents unwanted vessel movement during cutting operations

- Positioning control: Enables precise placement of the dredger in the work area

- Operational efficiency: Allows controlled swing movements around a fixed point

Most cutter suction dredgers use two spud systems: a working spud for primary anchoring and an auxiliary spud for additional stability. The working spud typically handles 70-80% of the anchoring load, while the auxiliary spud provides balance and prevents vessel drift.

“Without proper spud anchoring, a cutter suction dredger would be like trying to dig a precise hole while standing on a floating platform – nearly impossible to achieve accuracy.”

Types of Spud Systems in Cutter Suction Dredgers

Modern dredging operations rely on three main spud system types, each designed for specific operational requirements and environmental conditions.

Fixed Spud Systems

Fixed spuds represent the traditional approach to dredger anchoring. These systems use manually operated winches or simple hydraulic mechanisms to lower and raise the spud poles. Fixed systems work best in shallow water projects where frequent repositioning isn’t required.

Key characteristics of fixed spud systems:

- Lower initial investment costs

- Simple maintenance requirements

- Reliable performance in calm water conditions

- Limited repositioning flexibility

Hydraulic Spud Systems

Hydraulic spud systems represent the current industry standard for professional dredging operations. These advanced systems use hydraulic cylinders and power units to provide precise control over spud positioning and load management.

Hydraulic spud system components including power unit and control cylinders

The hydraulic approach offers several operational advantages:

- Remote operation: Complete control from the dredging control room

- Free-fall functionality: Rapid spud deployment for better seabed penetration

- Load monitoring: Real-time feedback on anchoring forces

- Precise positioning: Millimeter-level accuracy in spud placement

Spud Carriage Systems

Spud carriage systems revolutionize dredging efficiency by allowing the vessel to move forward along the spud without complete repositioning. This technology significantly reduces operational downtime and improves project productivity.

The spud carriage mechanism enables operators to advance the dredger incrementally while maintaining anchoring stability. This approach proves especially valuable in large-scale projects where continuous forward movement is required.

How Spud Systems Work: The Complete Process

Understanding spud system operation helps operators maximize dredging efficiency and maintain safe working conditions. The complete process involves several coordinated steps that work together seamlessly.

Step 1: Initial Positioning and Deployment

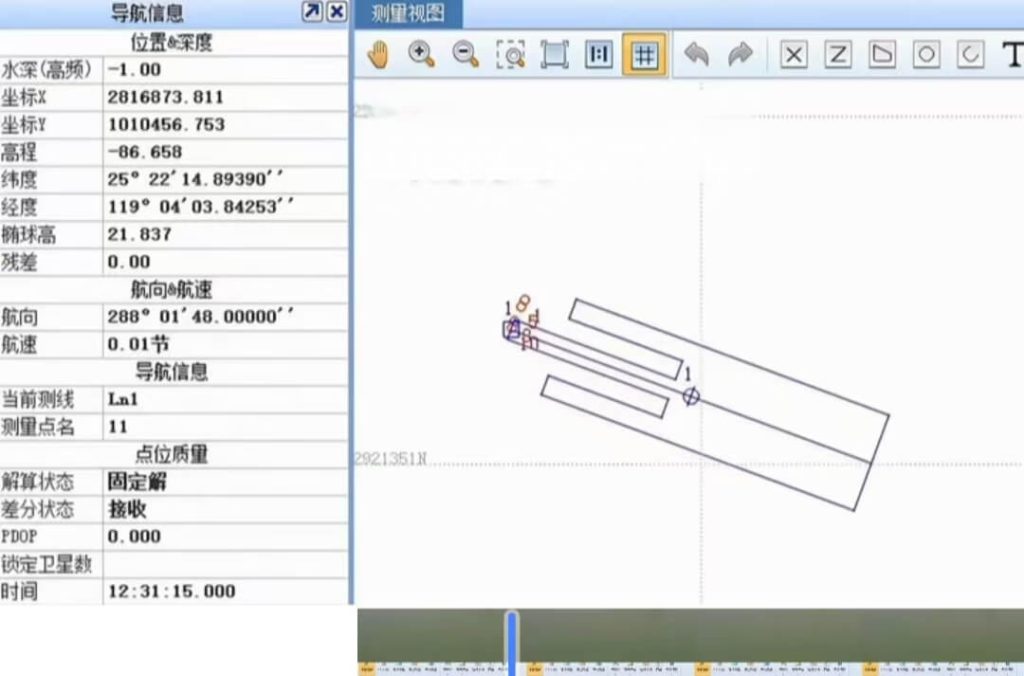

The dredging crew first positions the vessel over the designated work area using GPS and survey equipment. Once positioned correctly, operators lower the primary spud using hydraulic controls from the command center.

Modern spud systems feature free-fall capability, allowing the spud to drop rapidly under its own weight for better seabed penetration. This technique ensures secure anchoring even in challenging soil conditions.

Step 2: Load Distribution and Stabilization

After the primary spud achieves proper penetration, operators deploy the auxiliary spud to distribute anchoring loads evenly. This dual-spud approach creates mechanical equilibrium that prevents unwanted vessel movement during cutting operations.

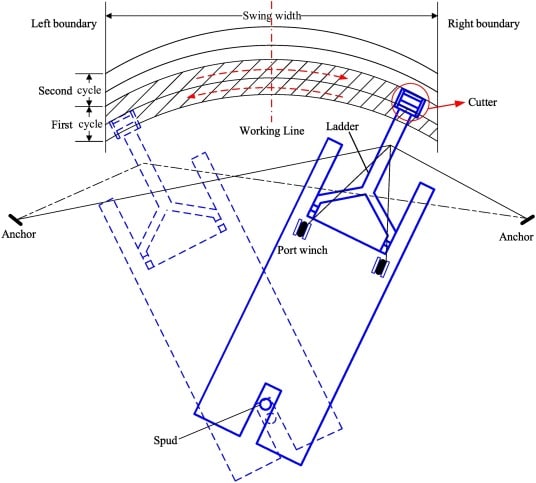

Dredger operating in controlled arc pattern around anchored spud system

Step 3: Controlled Dredging Movements

With spuds securely anchored, the dredger begins controlled movements around the work area. These movements follow specific patterns designed to maximize cutting efficiency:

- Swing movements: Side-to-side arcing around the primary spud

- Stroke movements: Forward and backward motion along the cutting path

- Stepping movements: Incremental forward advancement using spud carriage systems

Each movement type serves a specific purpose in the overall dredging strategy. Operators coordinate these movements to achieve optimal soil removal while maintaining precise depth control.

Force Balance and Mechanical Equilibrium

Effective spud anchoring relies on careful force balance between environmental loads and anchoring capacity. Wind, wave, and current forces create dynamic loads that the spud system must counteract continuously.

Research shows that environmental loads can vary significantly during operations. Advanced spud systems use finite element modeling to predict load variations and optimize anchoring performance under changing conditions.

Advanced Spud Technology and Innovations

The dredging industry continues advancing spud technology through digital integration and improved engineering approaches. These innovations focus on operational efficiency, environmental sustainability, and predictive maintenance capabilities.

Modern Hydraulic Spud Hoisting Systems

Today’s hydraulic spud systems handle impressive load ranges from 3 tons for small dredgers up to 125 tons for large-scale operations. This wide capacity range allows manufacturers to customize spud systems for specific project requirements.

Advanced hoisting systems incorporate several key features:

- Variable speed control: Adjustable lowering and raising speeds based on soil conditions

- Load limiting systems: Automatic protection against overload conditions

- Emergency release mechanisms: Quick spud extraction in emergency situations

- Synchronized operation: Coordinated control of multiple spud systems

Digital control interface providing precise spud system management

Digital Controls and Smart Integration

Modern spud systems integrate with comprehensive dredging management software that monitors operational parameters in real-time. These digital solutions provide operators with detailed insights into system performance and environmental conditions.

Smart spud systems monitor key performance indicators including:

- Anchoring load distribution across multiple spuds

- Environmental force vectors affecting vessel stability

- Hydraulic system pressure and temperature readings

- Spud penetration depth and soil resistance measurements

Predictive Maintenance Using Advanced Modeling

Predictive maintenance represents a significant advancement in spud system reliability. Recent research explores Gaussian process modeling for monitoring spud component condition and predicting maintenance requirements.

This approach uses machine learning algorithms to analyze operational data and identify potential failure modes before they occur. Predictive maintenance reduces unplanned downtime and extends equipment service life significantly.

Eco-Friendly Design Innovations

Environmental considerations drive many recent spud system innovations. Manufacturers focus on reducing hydraulic fluid consumption, minimizing noise generation, and improving energy efficiency throughout the system.

Eco-friendly spud innovations include:

- Biodegradable hydraulic fluids for marine environments

- Energy recovery systems that capture lowering energy for reuse

- Noise-dampening materials to reduce environmental impact

- Leak-proof sealing systems to prevent fluid contamination

Engineering Considerations for Spud Design

Spud design requires careful consideration of multiple engineering factors to ensure reliable performance under demanding operational conditions. Engineers must balance structural strength, operational flexibility, and cost-effectiveness in every design decision.

Material Specifications and Construction Standards

Grade A steel remains the industry standard for spud construction due to its excellent strength-to-weight ratio and corrosion resistance properties. However, material selection involves several specific considerations:

- Wall thickness optimization: Balanced approach between structural strength and weight management

- Reinforced lower sections: Enhanced strength at high-stress seabed contact points

- Corrosion protection systems: Multi-layer coatings designed for marine environments

- Stress concentration management: Rounded transitions and optimized geometry to minimize failure points

Detailed engineering specifications for spud construction and reinforcement

Dynamic Environmental Load Factors

Environmental forces create complex loading patterns that spud systems must withstand continuously. Wind, wave, and current forces interact dynamically, creating variable stress patterns throughout the spud structure.

Engineers use sophisticated modeling techniques to predict these dynamic loads accurately. Finite element analysis helps identify stress concentrations and optimize structural design for maximum reliability under harsh sea conditions.

Key environmental load considerations include:

- Wave-induced cyclic loading: Repetitive stress patterns that can cause fatigue failures

- Current-generated lateral forces: Steady loads that affect spud bending moments

- Wind pressure variations: Variable forces that change with weather conditions

- Combined load scenarios: Worst-case combinations of environmental factors

Reliability-Based Structural Optimization

Modern spud design incorporates reliability-based design optimization (RBDO) principles that consider randomness in loads, material properties, and geometric variations. This approach ensures economic yet robust construction for large dredging vessels.

RBDO methods help engineers account for uncertainties in:

- Material strength variations within manufacturing tolerances

- Environmental load fluctuations over operational lifetime

- Geometric imperfections introduced during fabrication

- Operational load patterns specific to different dredging projects

The comprehensive approach to cutter suction dredger design integrates these reliability principles throughout the entire vessel, ensuring coordinated performance between spud systems and other critical components.

Spud System Performance and Specifications

Understanding spud system performance metrics helps operators select appropriate equipment for specific dredging projects and optimize operational efficiency throughout the project lifecycle.

Load Capacity Ranges and Operational Depths

Modern spud systems accommodate diverse operational requirements through scalable design approaches. Load capacities range from compact 3-ton systems for small harbor maintenance up to massive 125-ton systems for major land reclamation projects.

Typical load capacity classifications:

- Light-duty systems (3-15 tons): Ideal for river dredging and small port maintenance

- Medium-duty systems (15-50 tons): Suitable for coastal protection and channel deepening

- Heavy-duty systems (50-125 tons): Required for large-scale land reclamation and deep-water projects

Operational depth capabilities typically extend up to 30 meters, though specialized systems can handle greater depths for specific applications. Depth capability depends on spud length, hydraulic system capacity, and vessel stability requirements.

Performance comparison showing spud system capabilities across different applications

Production Efficiency Improvements

Advanced spud systems significantly improve dredging productivity through several key mechanisms. Efficient spud positioning reduces cycle times and enables more precise excavation control.

Productivity improvements typically include:

- Reduced repositioning time: Faster spud deployment and extraction cycles

- Improved positioning accuracy: Better material removal rates through precise placement

- Enhanced stability: Consistent cutting performance in challenging conditions

- Automated positioning: Reduced operator workload and human error potential

Industry data shows that modern spud systems can improve overall dredging productivity by 15-25% compared to older fixed systems, primarily through reduced downtime and improved operational precision.

Market Data and Growth Trends

The global cutter suction dredger market experiences steady growth driven by increasing infrastructure investments and coastal protection requirements. Market analysis indicates continued expansion over the next decade.

Key market drivers include:

- Growing demand for port expansion and deepening projects

- Increased investment in coastal protection and land reclamation

- Rising focus on environmental dredging and contaminated sediment removal

- Technological advancement in dredging equipment efficiency

Regional growth patterns show particularly strong demand in Asia-Pacific markets, driven by major infrastructure development projects and increasing trade volumes requiring expanded port facilities.

Maintenance and Troubleshooting Guide

Proper maintenance keeps spud systems operating reliably while preventing costly failures that could halt dredging operations. A systematic approach to maintenance planning ensures optimal performance throughout equipment service life.

Common Hydraulic System Issues

Hydraulic spud systems face several recurring maintenance challenges that operators can address through proper monitoring and preventive care. Understanding these common issues helps maintenance teams respond quickly when problems arise.

Most frequent hydraulic system problems:

- Oil level fluctuations: Caused by internal leakage, external leaks, or inadequate reservoir capacity

- Synchronization problems: Uneven cylinder movement due to control valve issues or trapped air

- Pressure irregularities: Inconsistent system pressure affecting lifting capacity and control precision

- Seal deterioration: Gradual seal degradation leading to fluid leakage and reduced efficiency

Regular inspection of hydraulic system components ensures reliable spud operation

Preventive Maintenance Checklist

A comprehensive maintenance schedule prevents unexpected failures and extends equipment service life significantly. The following checklist covers essential maintenance activities organized by frequency:

Daily maintenance tasks:

- Check hydraulic fluid levels in all reservoirs

- Inspect visible seals and connections for leakage

- Verify spud positioning accuracy through test cycles

- Monitor system pressure readings during operation

Weekly maintenance activities:

- Test emergency spud release mechanisms

- Inspect spud structural components for wear or damage

- Check hydraulic filter condition and replace if necessary

- Verify synchronization between multiple spud cylinders

Monthly comprehensive inspections:

- Perform complete hydraulic system pressure testing

- Inspect spud guide systems and bushings for wear

- Check electrical control system connections and components

- Review maintenance logs and identify recurring issues

Troubleshooting Steps for Common Problems

When spud system problems occur, systematic troubleshooting helps identify root causes quickly and implement effective solutions. The following procedures address the most common operational issues.

Problem: Spud won’t lower or raise properly

- Check hydraulic fluid level and add fluid if necessary

- Verify system pressure meets manufacturer specifications

- Inspect control valve operation and clean if required

- Check for trapped air in hydraulic cylinders and bleed system

- Examine mechanical components for binding or obstruction

Problem: Uneven spud movement or poor synchronization

- Compare individual cylinder pressures to identify imbalances

- Inspect flow control valves and adjust as needed

- Check for air bubbles in hydraulic lines and purge system

- Verify equal loading on all spud cylinders

- Calibrate position sensors and control system feedback

Advanced troubleshooting may require specialized diagnostic equipment and manufacturer support. Complex problems involving control system integration should involve qualified technicians familiar with the specific spud system design.

The relationship between spud maintenance and overall dredger component maintenance requires coordinated scheduling to minimize operational disruptions while ensuring all systems receive proper attention.

FAQ Section

These frequently asked questions address common concerns about cutter suction dredger spud systems and provide practical answers for operators and project managers.

What is the primary purpose of spuds on a cutter suction dredger?

Spuds serve as massive anchoring systems that secure the dredger firmly to the seabed during operations. They create a stable pivot point that allows the vessel to perform precise cutting movements while maintaining exact positioning. Without proper spud anchoring, accurate dredging would be impossible due to vessel drift caused by currents, waves, and wind forces.

How does a hydraulic spud system work compared to fixed systems?

Hydraulic spud systems use pressurized fluid power to raise and lower spuds with precise control from the dredging command center. Operators can adjust positioning in real-time and monitor anchoring loads continuously. Fixed systems rely on manual winches or simple mechanical devices that require more time for positioning and offer limited control precision during operations.

What are the advantages of spud carriage systems over traditional anchoring?

Spud carriage systems allow the dredger to advance incrementally along the spud without complete repositioning, significantly reducing operational downtime. Traditional systems require lifting and repositioning spuds for forward movement, which interrupts dredging operations. Carriage systems improve productivity by 20-30% in projects requiring continuous forward advancement.

What factors determine the required spud system capacity for a project?

Spud capacity requirements depend on vessel size, environmental conditions, operational depth, and soil characteristics. Larger dredgers require higher capacity systems to maintain stability. Harsh weather conditions and strong currents increase anchoring load requirements. Projects in deeper water or challenging soils may need specialized high-capacity systems for reliable anchoring performance.

How often should hydraulic spud systems undergo maintenance?

Daily maintenance includes fluid level checks and visual inspections for leaks. Weekly maintenance covers filter changes and synchronization testing. Monthly comprehensive inspections examine all system components and performance parameters. Annual overhauls should include complete system disassembly, component replacement, and performance verification by qualified technicians.

What safety considerations apply to spud system operation?

Spud systems require careful attention to load limits, emergency release procedures, and personnel safety zones. Operators must monitor environmental conditions continuously and avoid exceeding system capacity limits. Emergency procedures should include rapid spud extraction methods for severe weather or equipment failures. Personnel should maintain safe distances from moving spud components during operation.

Can spud systems be retrofitted to existing dredgers?

Many existing dredgers can accommodate spud system upgrades, though modifications depend on vessel structure and available space. Hydraulic system additions require power supply integration and control system updates. Structural modifications may be necessary to support increased spud loads. Professional engineering evaluation determines retrofit feasibility and required modifications for specific vessels.

Conclusion

Understanding spud system selection, operation, and maintenance helps dredging professionals make informed decisions that optimize project outcomes. Whether planning new dredging operations or upgrading existing equipment, proper spud system specification ensures reliable performance in demanding marine environments.

The growing global demand for dredging services, driven by infrastructure development and environmental projects, continues pushing spud technology advancement. Future innovations will likely focus on further automation, improved environmental sustainability, and enhanced integration with digital dredging management systems.