Quick Facts: CSD Benefits for Lagos Calabar Project

| Feature | Cutter Suction Dredger | Other Dredger Types |

|---|---|---|

| Soft Sediment Performance | Excellent | Limited |

| Cost Efficiency | High | Moderate |

| Material Reuse Capability | Superior | Basic |

| Long-Distance Transport | Efficient | Challenging |

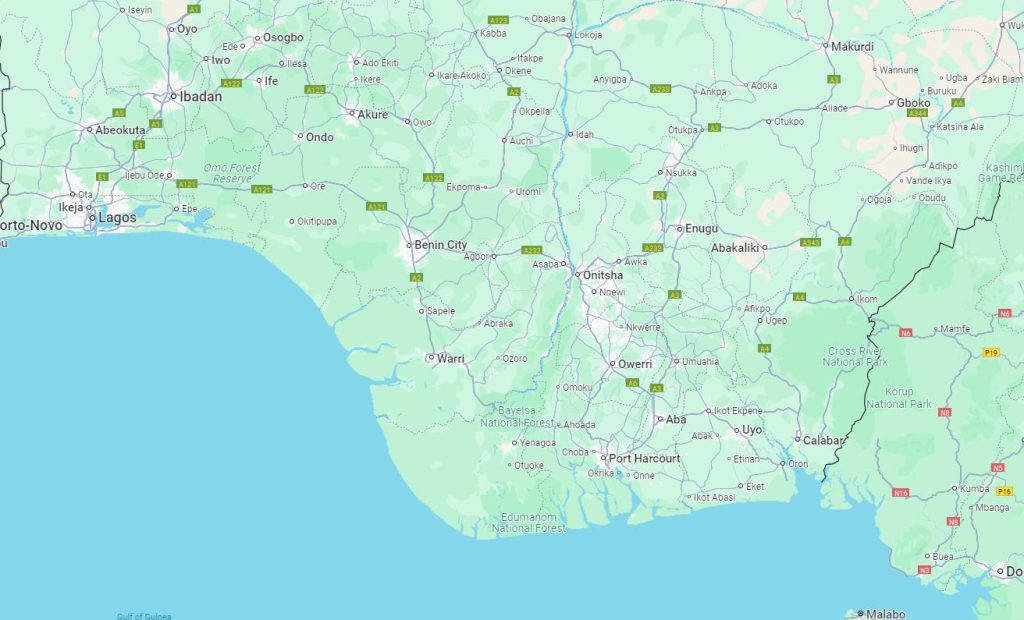

Nigeria’s ambitious Lagos Calabar Coastal Road project faces a critical challenge. Building a 700-kilometer highway across coastal terrain requires moving millions of cubic meters of underwater sediment. Here’s the problem: choosing the wrong dredging equipment could delay Africa’s largest infrastructure project by years.

The solution? Cutter Suction Dredgers specifically designed for Nigeria’s unique deltaic conditions.

Lagos Calabar Coastal Road: A Dredging Challenge

The Lagos Calabar Coastal Road represents Nigeria’s most ambitious infrastructure undertaking. This massive highway project stretches along Nigeria’s coastline, connecting major economic centers while crossing numerous waterways and wetlands.

However, building a highway across coastal terrain isn’t like constructing regular roads. The project requires extensive land reclamation work. Engineers must transform underwater areas into solid ground capable of supporting heavy traffic loads.

The scale is staggering. Construction teams need to dredge approximately 50 million cubic meters of sediment. They must also create stable embankments spanning hundreds of kilometers. Additionally, the project involves preparing foundations for over 100 bridge structures.

“The Lagos Calabar project requires precision dredging operations that can handle Nigeria’s complex coastal environment while maintaining environmental compliance.” – Nigerian Infrastructure Development Commission

According to the Vanguard Nigeria, this highway will boost economic activities across nine states. The project’s success depends heavily on efficient dredging operations that can work in Nigeria’s challenging coastal conditions.

Understanding Nigeria’s Deltaic Soil Conditions

Nigeria’s coastal region presents unique challenges for construction equipment. The Niger Delta contains some of the world’s most complex sediment compositions. Understanding these conditions is crucial for selecting appropriate dredging equipment.

The coastal soil consists primarily of soft clay, loose silt, and fine sand deposits. These materials have accumulated over thousands of years through river deposits and tidal actions. The sediment layers can reach depths of 30 meters or more in some areas.

Key Soil Characteristics:

- High water content: Often exceeding 80% in upper layers

- Low bearing capacity: Requires extensive ground improvement

- Variable composition: Changes dramatically across short distances

- Organic matter presence: Contains decomposed vegetation and marine life

These conditions create specific challenges for dredging operations. Traditional excavation methods fail in such soft conditions. Heavy equipment often sinks or becomes immobilized. Moreover, the high water content makes material handling extremely difficult.

The Nigerian Geotechnical Association reports that deltaic soils require specialized equipment designed for soft sediment extraction. This is where cutter suction dredgers excel.

Why Cutter Suction Dredgers Are Perfect for Lagos Calabar Project

Cutter suction dredgers solve Nigeria’s coastal construction challenges through superior engineering design. These machines excel in soft sediment conditions where other equipment fails.

First, CSDs feature powerful rotating cutters that slice through soft materials efficiently. The cutter head breaks up cohesive soils and mixes them with water. This creates a slurry that’s easy to pump through pipelines.

Second, the suction system provides continuous material removal. Unlike bucket dredgers that work in cycles, CSDs maintain steady production rates. This consistency is crucial for large-scale projects like the Lagos Calabar road.

Modern CSD operating in deltaic conditions similar to Lagos Calabar project

Third, CSDs offer exceptional cost-effectiveness for large volumes. Their operating costs remain low even during extended operations. Fuel consumption stays reasonable compared to other dredging methods.

Finally, these dredgers adapt well to variable terrain conditions. The Lagos Calabar route crosses different soil types and water depths. CSDs can adjust their operations without major modifications.

For detailed technical specifications, explore our comprehensive cutter suction dredger guide which covers all aspects of CSD operations.

How to Choose the Right Cutter Suction Dredger

Selecting the appropriate CSD for the Lagos Calabar project requires careful analysis of multiple factors. The wrong choice could result in delays, cost overruns, and operational difficulties.

Soil Penetration Requirements: Nigeria’s coastal soils vary significantly along the route. Some areas contain hard clay layers beneath soft sediments. Others have loose sand deposits throughout. The CSD must handle these variations effectively.

Choose a dredger with adjustable cutter power. Variable speed controls allow operators to adapt to changing soil conditions. Additionally, ensure the cutter head design matches the expected soil types.

Pumping Distance and Capacity: The Lagos Calabar project requires moving materials over considerable distances. Some reclamation areas are located several kilometers from dredging sites.

Calculate total pumping distances including horizontal and vertical components. Factor in pipeline friction losses and elevation changes. Select a CSD with adequate pump power for these requirements.

Selection Checklist:

- Verify soil penetration capabilities match site conditions

- Confirm pumping capacity exceeds project requirements by 20%

- Check environmental compliance certifications

- Evaluate spare parts availability and service support

- Review manufacturer’s track record on similar projects

Local Hydrological Conditions: Nigeria’s coastal waters experience significant tidal variations. Water levels can change by several meters during tidal cycles. The CSD must operate effectively across these ranges.

Consider dredgers with flexible positioning systems. Spud-pole systems work well in shallow waters. Anchor systems provide stability in deeper areas.

CSD cutter head designed for soft sediment penetration

Understanding cutter teeth performance and selection is crucial for optimizing dredger performance in Nigeria’s challenging conditions.

CSD Operations Methods for Coastal Highway Construction

Cutter suction dredgers serve multiple critical functions in the Lagos Calabar project. Each operation requires specific techniques and careful planning.

Land Reclamation and Roadbed Foundation: CSDs extract sand and sediment from designated borrow areas. The material gets pumped to reclamation sites where it forms new land areas.

The process begins with site survey and marking. Operators position the CSD at optimal locations for material extraction. The cutter head penetrates the seabed while the suction system removes loosened material.

Dredged material flows through pipelines to reclamation areas. Geotextile barriers contain the material while excess water drains away. This creates stable ground suitable for highway construction.

Bridge Site Preparation and Clearing: The highway crosses numerous waterways requiring bridge construction. CSDs prepare these sites by removing soft sediments and debris.

Pre-construction dredging ensures stable foundations for bridge piers. The CSD removes unsuitable materials down to competent bearing strata. This prevents settlement issues that could compromise bridge safety.

Bridge foundation site preparation through precision dredging

Embankment Construction: Highway embankments require millions of cubic meters of fill material. CSDs provide this material by extracting suitable sand from approved sources.

The sand must meet specific engineering requirements. Grain size distribution, plasticity, and organic content all affect suitability. CSDs can selectively extract appropriate materials while leaving unsuitable sediments in place.

Flood Risk Mitigation: Coastal highways face constant flood threats. CSDs help mitigate these risks by improving drainage systems and deepening waterways.

Strategic dredging creates better water flow patterns. This reduces flooding potential in adjacent areas. Additionally, improved drainage protects the highway from water damage during heavy rains.

Advanced CSD Techniques for Long-Distance Material Transport

The Lagos Calabar project’s massive scale requires innovative material transport solutions. Traditional direct pumping methods face limitations over long distances.

Storage Pit Integration: Advanced CSD operations use intermediate storage pits to overcome distance limitations. The dredger pumps material to nearby storage areas. Secondary pumping systems then transport material to final destinations.

This approach offers several advantages. It reduces the primary dredger’s pumping load, allowing faster material extraction. Multiple storage pits can supply different construction areas simultaneously.

Storage pits also provide material quality control opportunities. Sediments can settle and separate before final placement. This improves the quality of fill materials used in highway construction.

Pipeline Network Optimization: Complex projects like Lagos Calabar require sophisticated pipeline systems. Engineers design networks that minimize energy consumption while maximizing efficiency.

Pipeline routing considers terrain features, environmental constraints, and construction schedules. Booster pumps overcome elevation changes and friction losses. Multiple discharge points allow flexible material placement.

Advanced Transport Benefits:

- Increased efficiency: Up to 40% faster material placement

- Reduced environmental impact: Minimizes truck traffic and emissions

- Better quality control: Allows material processing before placement

- Operational flexibility: Enables simultaneous multi-site supply

Sediment Reuse Strategies: Environmental regulations emphasize sustainable construction practices. CSDs excel at controlled sediment collection and precise placement.

The dredged material serves multiple purposes in highway construction. Clean sand becomes concrete aggregate. Suitable soils create embankment fill. Even organic materials can be processed for landscape restoration.

Learn more about efficient material handling through our sand pump machine guide which covers advanced extraction techniques.

Economic Benefits of Using CSDs

Cutter suction dredgers deliver substantial economic advantages for the Lagos Calabar project. These benefits extend beyond simple cost savings to include broader economic impacts.

Lower Operating Costs: CSDs maintain lower fuel consumption rates compared to other dredging methods. Their continuous operation reduces per-cubic-meter costs significantly.

Maintenance requirements remain manageable with proper care. The robust design handles harsh coastal conditions without frequent repairs. This reliability translates to consistent production rates and predictable costs.

According to World Bank studies, CSD operations typically cost 30-50% less than alternative dredging methods for large-scale coastal projects.

Accelerated Project Timelines: Fast material extraction speeds up overall construction schedules. CSDs can operate 24 hours daily when conditions permit. This continuous operation significantly reduces project duration.

Shorter project timelines mean earlier economic benefits. The highway starts generating returns sooner through improved transportation and trade. Additionally, reduced construction periods minimize disruption to local communities.

Reduced External Material Sourcing: Traditional construction methods often require importing materials from distant quarries. This increases costs and environmental impacts through transportation.

CSDs utilize local sediment resources effectively. The dredged material meets most construction requirements after proper processing. This reduces dependence on external suppliers and associated logistics costs.

Economic impact analysis of CSD operations on large infrastructure projects

Local job creation through dredging and construction activities

Local Economic Stimulus: CSD operations create numerous employment opportunities. Local workers gain skills in equipment operation, maintenance, and support services.

The project also benefits local suppliers and contractors. Equipment maintenance, fuel supply, and logistics services all require local engagement. This multiplier effect amplifies the project’s economic impact.

Studies by the African Development Bank show that major infrastructure projects using local resources generate 2-3 times more local economic activity than projects relying on imported materials.

Leading Cutter Suction Dredger Manufacturers

The global CSD market includes several established manufacturers with proven track records. Understanding the key players helps project managers make informed equipment decisions.

European Manufacturers: European companies traditionally dominate the high-end dredging market. They offer advanced technology and comprehensive support services.

Companies like Royal IHC and Damen Shipyards provide cutting-edge dredging solutions. Their equipment features advanced automation and environmental protection systems. However, these advantages come with premium pricing.

Asian Manufacturers: Asian manufacturers offer competitive alternatives with excellent value propositions. They focus on robust, cost-effective designs suitable for challenging conditions.

Chinese manufacturers have gained significant market share through competitive pricing and reliable performance. Their equipment handles harsh operating conditions while maintaining reasonable costs.

Key Selection Criteria: When choosing a CSD manufacturer, consider several critical factors beyond initial price.

Manufacturer Evaluation Points:

- Track record: Proven success on similar coastal projects

- Technical support: Available engineering and operational assistance

- Spare parts supply: Reliable parts availability and logistics

- Training programs: Comprehensive operator and maintenance training

- Warranty terms: Comprehensive coverage and responsive service

- Local presence: Regional offices and service centers

Quality Standards and Certifications: Reputable manufacturers maintain international quality certifications. Look for ISO 9001 quality management systems and relevant marine certifications.

Environmental compliance certifications are increasingly important. Equipment must meet local and international environmental standards. This includes emissions controls and ballast water management systems.

The International Maritime Organization sets global standards for marine equipment. Ensure selected manufacturers comply with relevant IMO regulations.

Customization Capabilities: Large projects like Lagos Calabar often require equipment modifications. Choose manufacturers with proven customization experience.

Customization might include special cutter head designs, extended pumping systems, or environmental monitoring equipment. The manufacturer should demonstrate ability to deliver these modifications reliably.

Choosing Your CSD Partner: Ocean Blue Company’s Expertise

After understanding the technical requirements and market options, selecting the right equipment partner becomes crucial. Ocean Blue Company brings over 25 years of specialized experience in manufacturing cutter suction dredgers designed for challenging coastal conditions.

Our extensive experience includes successful projects across diverse international markets. From the challenging conditions in Argentina’s coastal regions to the complex requirements of Uzbekistan’s inland waterways, we’ve proven our equipment’s reliability in varied environments.

Customized Solutions for Nigerian Conditions: We understand that Nigeria’s deltaic environment requires specialized equipment configurations. Our engineering team designs CSDs specifically optimized for soft sediment conditions common along the Lagos Calabar route.

Our cutter suction dredgers feature enhanced cutter head designs that excel in soft clay and loose sand conditions. The powerful suction systems maintain efficiency even in high water content materials.

Comprehensive Support Services: Beyond equipment supply, we provide complete project support. Our services include site assessment, equipment selection guidance, and operational training for local crews.

Transportation logistics often challenge large dredging projects. Our experience with dismountable cutter suction dredger transportation ensures smooth equipment delivery to remote coastal locations.

Ocean Blue CSD optimized for deltaic soil conditions

Ocean Blue technical team providing on-site support and training

Proven International Track Record: Our equipment operates successfully in over 30 countries worldwide. This international experience provides valuable insights into diverse operating conditions and regulatory requirements.

Projects in Serbia’s Danube River system demonstrate our equipment’s versatility in European environmental standards. Operations in Argentina’s coastal regions prove reliability in challenging South American conditions.

Quality Assurance and Support: Every Ocean Blue CSD undergoes rigorous testing before delivery. Our quality control processes ensure equipment meets specifications and performs reliably in field conditions.

We maintain comprehensive spare parts inventories and provide rapid response support. Our technical team offers 24/7 consultation services to address operational challenges quickly.

Conclusion: Securing Nigeria’s Infrastructure Future

The Lagos Calabar Coastal Road represents more than just a transportation project. It’s Nigeria’s gateway to enhanced economic growth and regional connectivity. The project’s success depends critically on selecting appropriate dredging equipment that can handle Nigeria’s unique coastal challenges.

Cutter suction dredgers offer the ideal solution for this massive undertaking. Their superior performance in soft sediment conditions, combined with cost-effective operations and environmental compliance capabilities, makes them essential for the project’s success.

However, equipment selection alone isn’t sufficient. The manufacturer’s experience, support capabilities, and understanding of local conditions are equally important factors in project success.

Ready to discuss your coastal dredging project requirements? Ocean Blue Company’s experienced team stands ready to provide customized solutions for Nigeria’s challenging coastal conditions. Our 25+ years of international experience and proven track record in similar environments make us your ideal partner for critical infrastructure projects.

Contact Ocean Blue Company today to schedule a consultation with our technical experts. Let us help you select the right cutter suction dredger configuration for your specific project requirements. Visit sinooceanblue.com to explore our complete range of dredging solutions and discover why international clients trust our equipment for their most challenging projects.

Don’t let equipment limitations delay your coastal infrastructure project. Partner with Ocean Blue Company and ensure your project’s success with proven, reliable dredging technology.